The Nichols Banjo Bridge

The Nichols Banjo Bridge was created by my desire to improve the sound of my banjo. About 30 or so years ago, I was in my little wood shop and broke my banjo bridge. I had been experimenting with it and thinning it down and trying different things to enhance the sound of my banjo. I had tried a lot of things during this time including soaking the bridge in Danish Oil and even inserting a sound post between the head and top coordinator rod. I tried everything that I heard about and some of it worked and some of it didn’t. This was about the time when I made my first banjo bridge.

Here is an example of one of my early designs. I think this is dogwood. I made a lot of bridges from dogwood in the early days. The bottom of this bridge is compensated to allow for the way a head sags in the middle. It is pretty common for me to see a 3 footed bridge that looks like a banana on top because of this, especially if the banjo is played with a relatively loose head tension for a long time.

I discovered that the traditional shape of a 3 footed banjo bridge got increasingly weak as it got thinner. Of course this goes without saying. During this time, I was interested in getting the most volume I could from a banjo. This is probably a normal mistake for a young banjo player. I told someone a while back that I’d spent 20 years trying to make my banjo as loud as I could, and the last 20 trying to quieten it down as much as I could.

Here is an example of one of my wilder designs. I put one on Chris Painter’s old RB-250 and he kept it on there for a long time. He may still have it on there. It was a delicate style. This was made of red spruce with an ebony top. I made a lot of spruce bridges. I read an old article one time that said Don Reno had used a spruce bridge at one point. Reno apparently wasn’t afraid to try something a little different from everybody else. A spruce bridge made in the traditional 3 footed design would not hold up as well as my design with the lower end all connected. If you haven’t tried spruce, don’t laugh at the idea. My design allows me to make them a lot lighter in weight if I desire without compromising the strength.

Here is another bridge design that I tried a while back. Compensated top and hollow bottom.

I read an article years ago (I think it may have been in Banjo Newsletter) by some guy who said that he felt that having a hole or a blank space right under the string was an asset. After making a few traditional shaped bridges, I set about to design one that suited my ideas about sound. The first ones I made featured just some holes directly underneath the 5 strings. I experimented with solid bottoms on these bridges. By solid bottom, I mean a continuous piece of wood contacting the head across the entire width of the bridge.

Here is one with a solid bottom and a compensated string configuration.

I tried hollowing out little spaces on the bottom and creating 3 “feet”. I tried a lot of things before settling on my design.

Here is a different base. I guess this would be called a 2 footed bridge.

Here is a blank from spruce and ebony. I tried a lot of different configurations from these blanks.

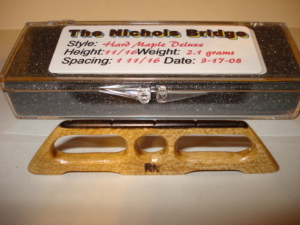

Here is one that pretty much represents what I have made for several years.

I tried to get a balance of wood versus air beneath this vibrating bridge. I tried a lot of designs.

I made compensated tops on them. I made straight tops for them. I made rounded shaped ones.

I made pyramid shaped ones. I made them curved on top and curved on bottom. I made them from every kind of wood I could get my hands on. I made them thick. I made them thin. I learned to weigh these bridges to compare the sound qualities. I now think the overall weight of the bridge is a BIG factor in the tone they produce. I made some from other materials besides wood including Micarta, Corian, fiberglass, aluminum, steel, brass, and other materials. I made them with rosewood tops, ebony tops, Corian tops, bone tops, and with no tops.

My good friend, Rual Yarbrough, liked a hard maple bridge with no ebony on top. I made this style bridge for him for the last few years of his life. Slim Johnson, a friend of mine, gave one of my bridges to a fellow named Clyde (I think it was Hargus). Clyde took it and showed it to Rual. Rual liked it and called me and we developed a friendship quickly. Like me, he wasn’t afraid to try something that looked a little different. Rual sold my bridges and put them on his banjos from that time forward. I respected him as a picker and also as a gentleman. I always enjoyed talking to him and hearing his stories about playing on the road and building, repairing, buying, selling, and trading old banjos. Rual knew (and played with) a lot of the famous musicians and he could tell some interesting stories about them. I miss him a lot now that he is gone. He was a true, non-egotistical gentleman.

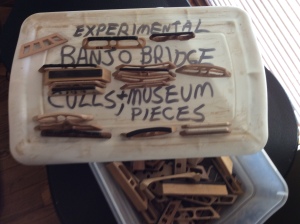

Most of these bridges I’ve shown came from my “Culls and Museum Pieces” box.

It seems like no matter what I tried, I always came back to the maple bridge. I said all this to demonstrate to what length I have gone in my banjo bridge making. I had another website several years ago and listed my bridges on it. I sold quite a few on Ebay a few years back. I sold them with an unconditional money back guarantee. I only had one fellow who was unhappy with his bridge. He said he used nylon strings on his banjo. I refunded his money and told him to keep the bridge and not to bother with shipping it back to me.

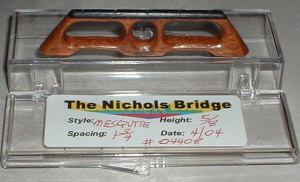

Here is one I’d forgotten about. It is mesquite and ebony. Mesquite makes a good banjo bridge. If you look real close you can see that I drilled some tiny holes in it and the string went through these holes. This was an attempt to get a cleaner sound without any buzzing or twanging. The sound produced by this was indeed clean but can you imagine breaking a string on stage and trying to feed a string through this little hole?

In the last few years I’ve gotten away from trying to market these bridges. I have become increasing impatient with banjo players who seem to be searching for something and really don’t know what it is they seek. They talk about the “pre-war” sound. Tone is hard to describe and I doubt if most of them would know the “pre-war” sound if they heard it. I saw a reluctance to try something different if some big named player didn’t endorse the product. I’m sure this is no different than any other products for sale out there. I’ve never claimed that my bridges were the best thing out there. I did market them as being able to hold the strings above the head of a banjo.

Update:January 2, 2018

A few months ago my wife and I were walking through an antique mall. I saw an old style school desk that had metal sides and a wooden top and seat. It had the hole in the top for an ink well. Upon examining it, I saw that it was hard maple. I purchased it and brought it to my shop and sawed some bridge blanks from it.

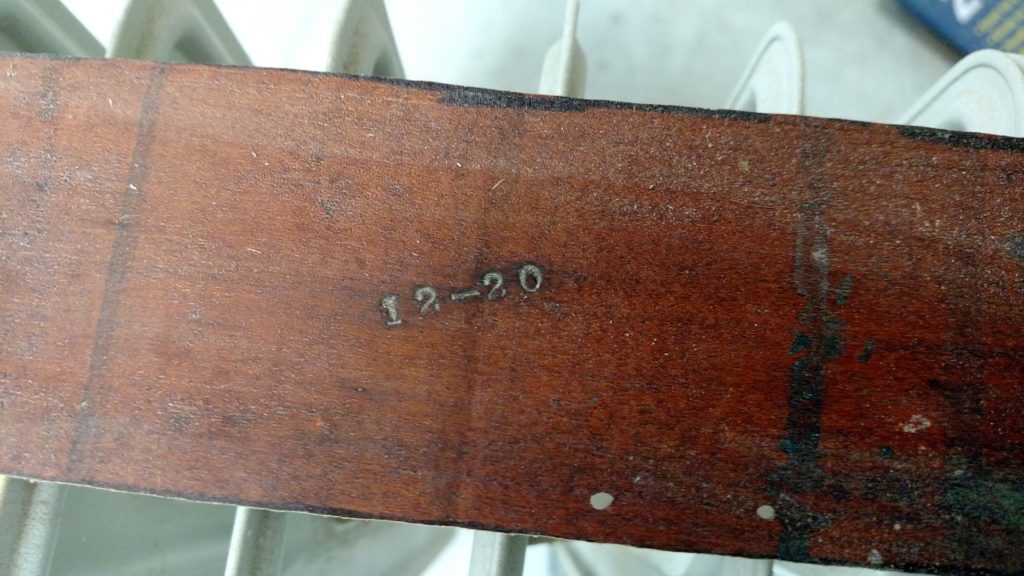

The pieces were about 3/4 inch thick and the grain was oriented right in most pieces. In sawing it up, I found a date stamped in the underside of the top. I was 12/20. This wood was harvested sometime before December, 1920 so it is around 100 years old. It has the speckled look to it that seems to make a good banjo bridge. I made several bridges from this wood and they were GOOD.

I previously made a video where I replaced the top in my guitar with some torrefied wood. (There is a link on this website to that video) This wood made a BIG difference in the sound of that guitar. A fellow brought a banjo to my shop recently and he had a roasted maple bridge on it that came from First Quality Music. This bridge got my attention. It sounded great on his banjo. So, being the guy I am, I wondered what a little roasting would do to this 100 year old wood. Below are some pictures of the before and after bridge blanks. If these bridges already sounded as good as they did, I had to find out what roasting some of them would do. So, I put several in a little toaster oven and baked them for a while. When they came out, they were a darker color and it made them harder to machine. The only negative I found was that the wood got to be sort of brash with a tendency to split while machining, but I think the good points outweigh the bad. I really think these roasted 100 year old bridges are among the best I’ve ever made.

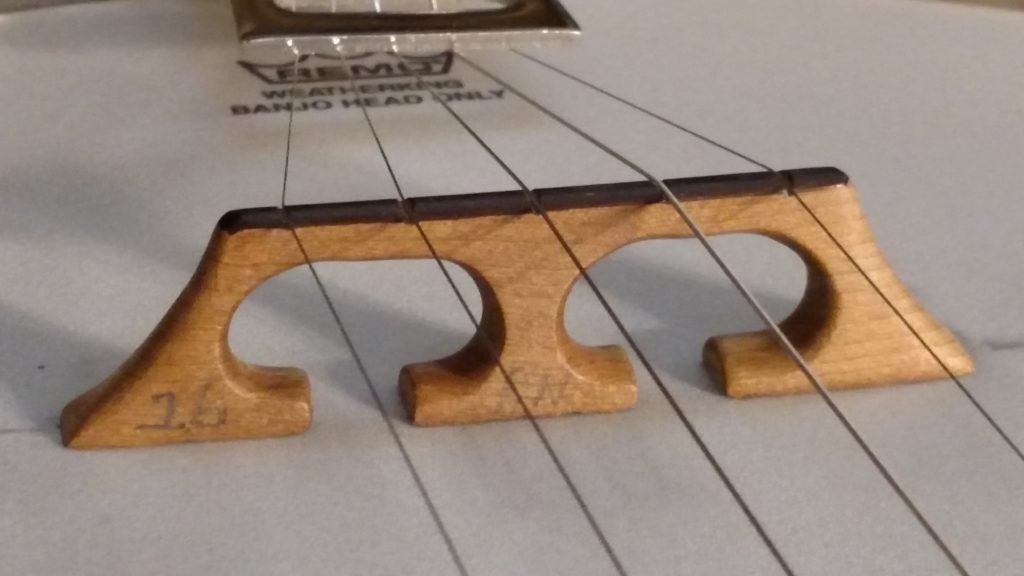

I also went back to something similar to the traditional 3 footed style bridge for this run of bridges (talk about going in a BIG circle and coming back to where you started!). They have been a big improvement on any banjo they have been put on. I use a tall bridge on my banjos because my picking style demands that I have some extra clearance between the strings and head. Also, I usually don’t put an ebony top on these bridges. Rual Yarbrough got me interested in this way of making them and they work well for me. I darken the tops with a black magic marker. Rual told me years ago that people wouldn’t even try a bridge without a dark top on it. These bridges have improved the tone of my 2 banjos that have Huber pots. I’ve also put one of these bridges on one of my prewar, ball bearing banjos (trapdoor conversions) and they sounded good on it, too. I still make my original design. These traditional type bridges were just a limited run to test the tone of this roasted wood.

I’ve seen some great bridges made by a lot of makers. They have done their research and have endeavored to make the best product they can. Banjo bridges are a critical part of banjo tone. With a different bridge, you can vary the tone from deep bass to piercing treble or anywhere in between. The bridge is just one part of the puzzle of getting the tone you want from a banjo. You can read a lot of hype about all the tone rings and shells and tailpieces which are said to be important. I agree that these things are all important in the overall tone of a banjo. The tone comes from all these things together. The right combination is what makes your banjo have the sound YOU want. I make a limited number of these bridges nowadays. I prefer to have a banjo player come to my shop so we together can attempt to make a bridge that has the right tone for them.

![]()

Beautiful. I have a walnut open back I built. I would like a mesquite 5/8 deluxe design bridge.

Contact me at ronnienichols48@gmail.com and we’ll talk about making one for you. Thanks, Ronnie

Hi

been playing banjo and making banjo bridges for over 50 years and must agree ebony top will dull the tone

I tried an all ebony bride it kills the tone and volume I make my bridges with maple and 3/16 ebony inserts

TOM DEGNEY

The inserts are a good idea. I’ve never had a problem with the maple not being hard enough to hold the string. I’m sure the ebony is harder but the maple seems to do the trick pretty well for me. Thanks for your comments.

I would be very interested in purchasing one of your new bridges. I play the irish tenor banjo (GDAE), and I am looking for a rather heavy bridge, perhaps double the mass (or more)of a traditional bridge. I made a bridge myself, but it looks terrifying. (it makes your first bridge attempt look rather sophisticated) Tone wise I want steer hard toward thumpy and warm- I currently have a goldtone remo IT-250r (WL tonering and resonator)and I want to tame the strength and projection that this banjo already provides. I’m thinking the old/baked wood will provide clarity while the increased mass will support the low “G” and bring out the thump. Please email me! Thanks.

I sent you an email about this. Thanks for your interest! Ronnie

Hello,

Enjoyed your article and I have a Rual banjo and would like some insight as to what I have

would you please call me when you are able.

Thanks,

Willis Underwood

919-920-4421

That was a fascinating read, sir. I respect that even as you found designs that worked, you never stuck with them to the exclusion of innovation . Your workmanship is beautiful in it’s rounded and organic nature. I don’t know what tone I’m looking for from my banjos, but I love finding the tones that I’ve found. Would you consider making a bridge for me? I play two very different open back banjos, although both take a 5/8″ bridge. One is an eleven inch cherry with a greadillo tone ring and is very mellow and relaxing, the other is an eleven inch made from cast aluminium and a walnut neck that is very forward and excitable. Should you have any thoughts on a bridge for either of these banjos, I would be very happy to hear from you.

Thanks for your positive comments. I would consider making you a bridge. It sounds like your banjos are probably open backed ones. I’ve found that the weight of a bridge is a big factor in the tone. Generally it is my opinion that a lighter weight bridge usually is more treble sounding than a heavier one. Finding the right weight bridge that enhances the tone you seek is important. It is nice to have an assortment of bridges to try and see which weight matches your ear and your banjo. I realize that this is not possible for everyone. I’d recommend probably a bridge weighing around 2.4 to 2.6 grams made of hard maple. I’ve made them in all kinds of woods but it seems like I always come back to hard maple. I’ll be happy to work with you on this. You can contact me for further discussion at my email address: ronnienichols48@gmail.com

Thanks for your interest. Ronnie

Where do we get to purchase a bridge like this? Would love to try. Do you export to UK.

I can fabricate one for you, but I’m not familiar with what is involved to ship one to the United Kingdom. The price of one of these bridges is $30.00 plus the shipping. I’d need to know what height you want and the string spacing you require. I can take a PayPal payment. You can contact me for further information at my email address. It is

ronnienichols48@gmail.com Thanks for your interest. Ronnie Nichols

I have several dogwood blocks I got from my dad back when he worked for a company that made loom shuttles out of it. I would like to make a couple of banjo bridges but am curious about how you would rate the difference between dogwood and maple in terms of tone. Any tips would be appreciated. Enjoyed viewing your site and admiring your handiwork.

Mickey: I sent you an email with some of my opinions. Thanks For your kind comments. Ronnie Nichols

Love how you experiment.

I also do this and 2 designs are like yours.

My current one I think is totally original playing with violin ideas for 5 string banjo.

Love your work and I know how time consuming making them are.

Thanks for your kind comments! Keep on experimenting! Ronnie

Hey Ronnie I hope your doing well, I’m wanting a 5/8 banjo bridge with no ebony on top, like Raul Yarbrough, get back in touch on a price

Thanks, Elijah

Elijah, I sent you an email about that banjo bridge. Thanks for your interest.